Importance of Draining Inside Turbine Casing

Turbine casing drains remove the condensate from the turbine casing during warm-up securing maneuvering and other low flow conditions. This is warning device located on the top of the exhaust end turbine casing indicates excessive turbine exhaust end casing pressure.

It has to drain off the water coming out of the buckets without hindering the runner.

. Construction is mainly fabricated. In this work the temperature and stress distributions for turbine inner casing were calculated by finite element analysis. There are usually different types of casing like 1.

Turbine casing is determined because this parameter has a strong influence on casing integrity and residual life. In this situation the pump casing is drained into a closed drain. What does Casing mean.

Turbine casing drains remove the condensate from the turbine casing during warm-up securing maneuvering and other low flow conditions. Fill all grease cups and oil the governor and other miscellaneous parts. However it is always true that turbine should be on barring gear.

The results of residual life assessment provide not only a basis for further maintenance but also estimated time for reparation or renewal. Open drains on the steam line separator casing and exhaust lines. Turbine drain valve drains the casing to atmosphere.

The drains should be located on the boiler side of the throttle valve. Starting a small non condensing turbine like that. To design a more efficient steam turbine a casing with proper nozzles and vanes to confine the steam and valves to control the admission of steam to the nozzles should be used.

In addition it is necessary to drain all portions of the turbine casing where water from condensation may collect. Slowly open the exhaust-line shutoff valve. Directly to the turbine casing or else they are located inside of a nozzle diaphragm.

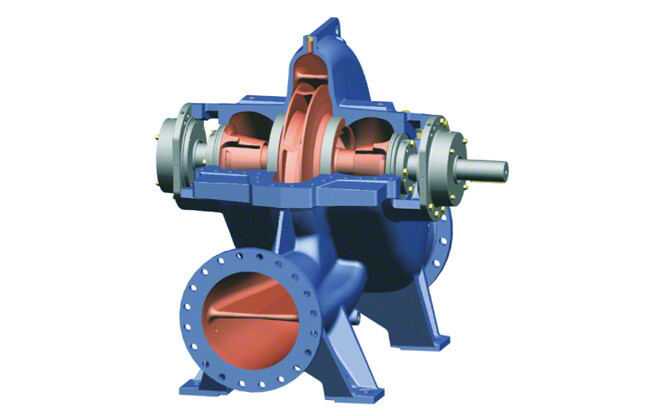

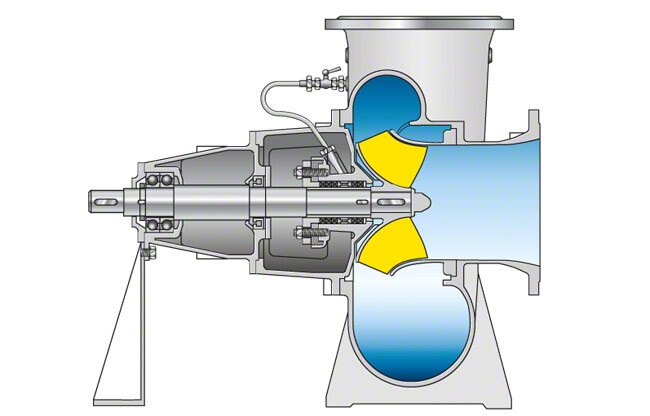

Pressures are relatively low and the casing is not as robust as in the higher pressure cylinders. The LP turbine is a pressure compounded either single or dual axial flow condensing reaction turbine. A requirement when the pumped fluid is of an explosive corrosive or poisonous nature.

The effluent must be discarded in a manner that will. However weld repair from steam or water droplet erosion can be difficult on. The top halves of the diaphragms are fixed in the casing by the same arrangement and lift with the casing cover.

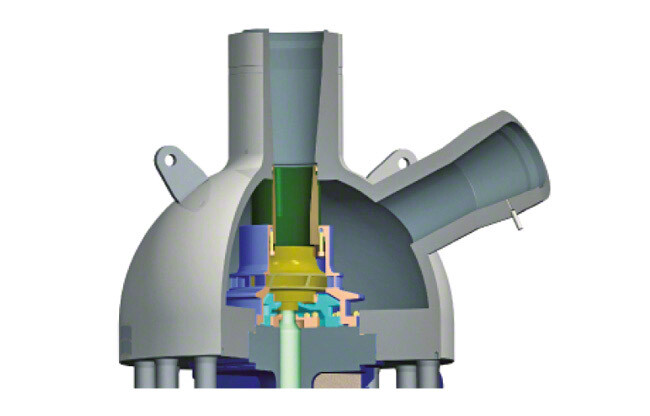

The provision of an inner casing confines high steam inlet conditions to the admission section of this casing while the joint flange of the outer casing is subjecting only to the lower pressure and temperature effective at the exhaust from the inner casing. Water in any pocket in a turbine casing may cause a slug of water to be carried over in the turbine during operation with very serious results. Casing may also refer to an enclosing shell tube or surrounding material.

Casing PKDhakan Abdul Basheer PC Hydel Research and Development Centre Jyoti Limited Vadodara India. The blades were designed to handle steam not water. In the event the casing pressure exceeds a predetermined setting above the normal operating pressure the valve.

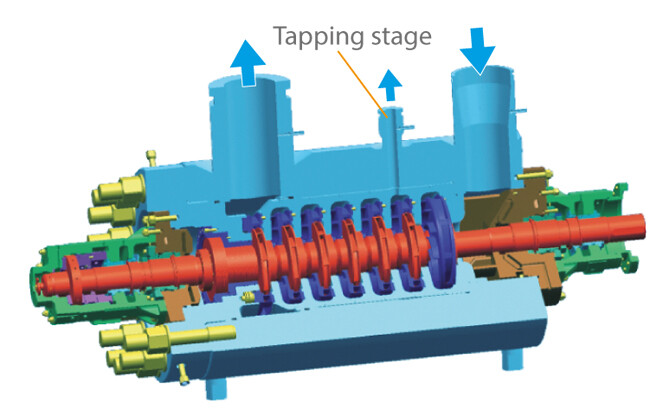

There is an inner casing supporting the fixed blading and annular channels through which steam is extracted for feedwater heating. CASE 1 COLD START TURBINE STARTING IN COLD CONDITION Rotor is big enough in length and is. This is the point of the open arrows inside the motor envelope.

Equipped with traps open the bypass line. Look at ASTM A 356 Grade 1 for cast carbon steel. When all draining is complete a foamed water solution like that used for the system integrity test is injected through the turbine to force out any remaining chemical solvent not previously drained.

The pump casing drain is shown having two valves. Modern steam turbines have an electronic governor that uses sensors to monitor the speed by examining the rotor teeth. There are two cases of particularly which this condition must be filled.

Turbine casing drains remove the condensate from the turbine casing during. The LP turbine see Figure 6 is located next to the HP turbine. This can break these components from impact.

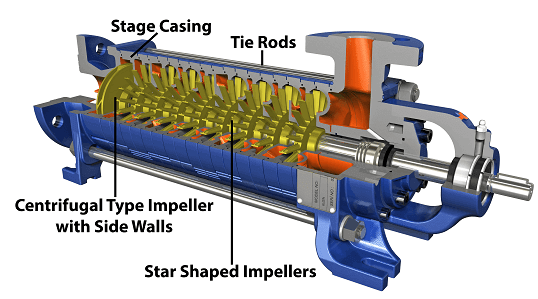

- Describes the importance of draining inside turbine casing - Describes with the aids of a sketchcomputer aided drawing function of gland packing steam - Explains the function of manoeuvring valve Explains the role of extraction steam Describes that gland steam pressure is controlled by make up valve and spill valve. The important components steam turbine casing is shells shaft-end packing head flange bolts inlet section and a diffuser 5 6. KeywordsRemaining life assessment creep-fatigue interaction high pressure steam turbine.

For the LP turbine inner casing rings I would use cast carbon steel. I have seen nodular cast iron as inner casing rings for old GE large LP steam turbines. Machine hence optimized design is required.

Turbine drains are necessary to avoid slugging nozzles and blades inside the turbine with condensate on start-up. To avoid slugging nozzles and blades inside the turbine with condensate on start-up. Steam Turbine Casing A turbine casing cylinder is a high pressure vessel with its weight supported at each end on the horizontal centre line.

Ok we have used casing vibration with a turbo-alternator and mill turbines like other companies that theres a plenty of time to overhaul after every milling. A cover or shell that protects or encloses something. 1 LP Turbine The casing of the double-flow LP cylinder is of three-shell design.

The reason is that cast carbon steel is weld repairable. Is of the The turbine casing houses and supports the turbine rotor labyrinth seals and bearings. Answer 1 of 6.

Steam turbine casing will be established by finite element method. Casing vibration is not totally futile as we have managed to used casing vibration at the alternator bearings for acceptance guide for alignment and etc. The one downward pointing open arrow carries leakage from the motors work ports and releases it into the internal cavity of the motor case.

Low pressure LP turbine. The three dimensional model of the Steam Turbine Casing was created using the. Surrounding the entire turbine is an exhaust hood into which the exhaust steam.

Answer 1 of 2. As turbine is a rotary mechanical device that extracts energy from a flowing fluid and converts it. The other open arrow points to the external case drain port and the implication is that it connects the case drain port to the.

The casing is an essential part of the turbine. This can break these components from impact. Safety utmost importance while operating the main engine.

Rapid Steam Turbine Replacement Md A Turbines

The Fossil Fuel Power Plants Technology Sciencedirect

Heavy Steel Casting Total Materia Article

Lower Casing With Diaphragms Installed And Turbine Rotor Removed Of A Ge Steam Turbine Kingston Jamaica Steam Turbine Turbine Gas Turbine

Split Casing Pump Troubleshooting Guide

Steam Turbine Flow Operation Processing Magazine

Steam Turbine Flow Operation Processing Magazine

Finding And Fixing Leakage Within Combined Hp Ip Steam Turbines Part Ii

What Ge Told Stug2020 Attendees About Its Steam Turbines Combined Cycle Journal

Gas Turbine Alignment Mda Turbines

Contact Pressure Validation Of Steam Turbine Casing For Static Loadin

Steam Turbine Archives Mda Turbines

Pdf The Role Of Nde In The Life Management Of Steam Turbine Rotors

Comments

Post a Comment